General Discussion

Related: Editorials & Other Articles, Issue Forums, Alliance Forums, Region ForumsThe Supply Chain is Way More Complex Than You Think It Is and It's Way More Messed Up Than You Know

The Supply Chain is Way More Complex Than You Think It Is and It's Way More Messed Up Than You Know

glendenb

Community (This content is not subject to review by Daily Kos staff prior to publication.)

Saturday September 25, 2021 · 2:38 PM EDT

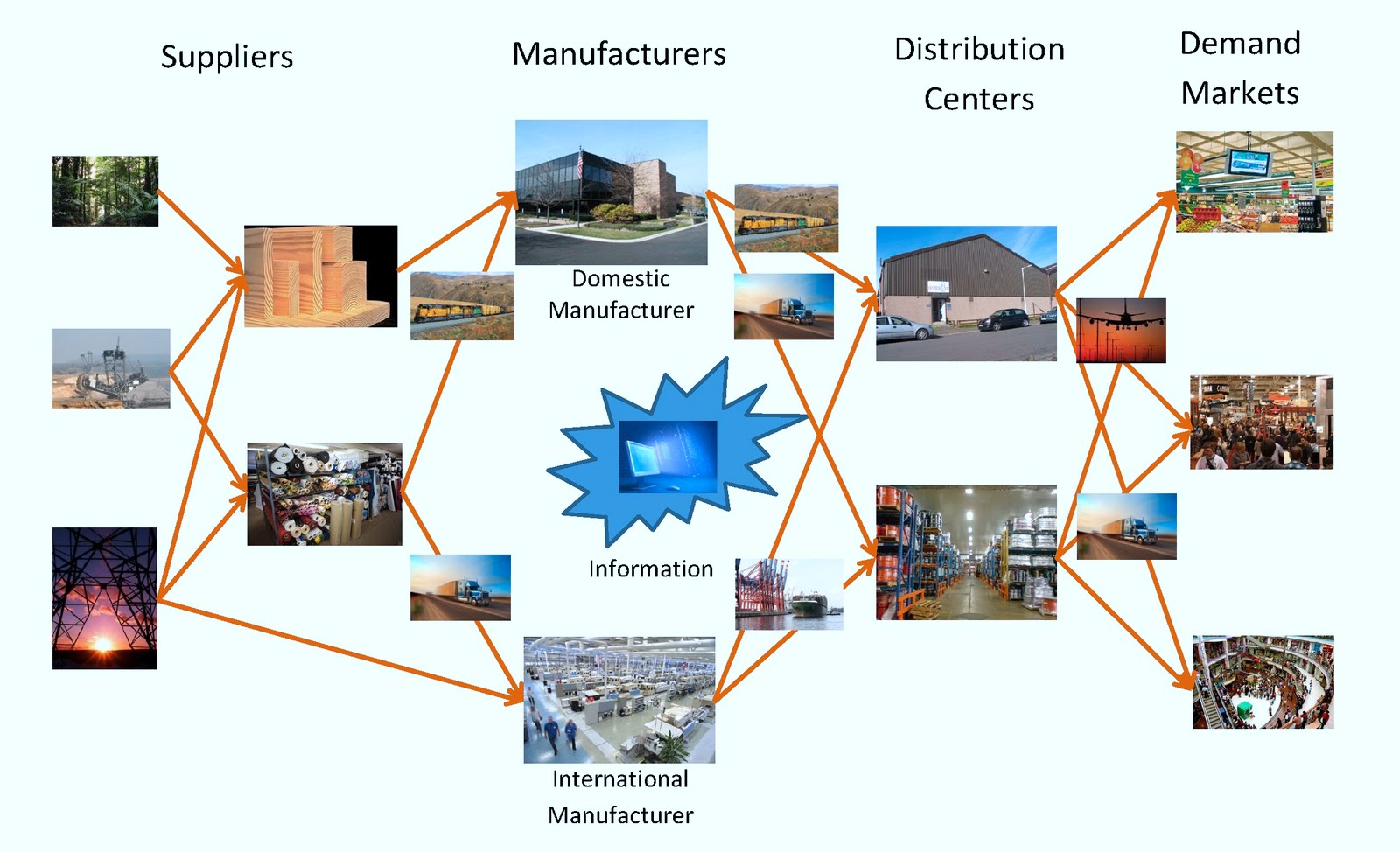

(Image found at www.newdesignfile.com/...)

For most of my career (over 20 years now), I’ve worked for distributors. I spend a significant amount of my time thinking about supply chain — how it works, where it works, where it breaks down. 2020 and 2021 have demonstrated both the robustness and vulnerability of the supply chain.

What is the supply chain:

The metaphor of the supply chain is helpful. It gives us a clear way to imagine product from raw material to end user. Raw materials go to manufacturers, who create the product, product goes to distributors who deliver it to retailers who sell to end users.

It’s a clean, clear, linear process.

Except it’s not.

more...very informative for those interested...

https://www.dailykos.com/stories/2021/9/25/2053968/-The-Supply-Chain-is-Way-More-Complex-Than-You-Think-It-Is-and-It-s-Way-More-Messed-Up-Than-You-Know

canetoad

(17,129 posts)I've noticed that the oddest things have been in short supply during the past couple of years of Covid. If I enquire the answer is usually, 'It's held up on a dock in Japan.'

![]()

babylonsister

(171,024 posts)I lived on Guam. There were always shortages and the standard excuse was, 'it's on the boat'.

![]()

GP6971

(31,100 posts)pretty correct. I spent my entire working career in logistics. One thing I took exception to is Our grocery store shelves may be full but the store rooms in back aren’t.. That used to be the case but that all changed in the late 80s when Just in Time delivery became the norm...Corp offices charged their distribution centers (and end users...the retailers) finance charges for the inventory on hand. So no, modern grocery stores don't have back rooms filled with stock...the grocery retailers rely on on 3 or 4 deliveries per week.

So one hiccup in the supply chain can have enormous implications.

Hortensis

(58,785 posts)were probably picking up again when my husband's crunchy peanut butter was out of stock.

During previous shortages it took me weeks to get the relationship through his head between just in time inventory and why I was buying "but we already have that" items when they were available. This is America, where the danger has always been from being swamped and drowned in the abundance.

![]()

House of Roberts

(5,157 posts)His days off now are the days when production gets held up by parts that don't arrive on time.

I used to work for an aviation parts supplier. We had to make ten planes' worth of parts, in the right order, and deliver them on time, for Gulfstream. It all had to ship just so, or the work got held up at their facility, and we got chewed out. So I've been in that supply chain in the middle, waiting on the right grade aircraft alloy aluminum, to be received and certified, then have to work a weekend to get the sequence back on track.

I've also had a machining process specify 4"x4" stainless steel, but the supplier could only get us 5"x5", requiring extra time to rough machine more material off each part blank, which meant the CNC programmers had to make new programs.

dixiegrrrrl

(60,010 posts)Gives a different perspective ofhow inter-global we all are.

Bloomberg has a newsletter that I like, called supply lines, with short snapshots of day to day shortages, blockages, etc. Always quite surprising.

It's a free email thing...if anyone is interested,one can request the reports here:

https://www.bloomberg.com/account/newsletters/supply-lines

Hortensis

(58,785 posts)Wingus Dingus

(8,052 posts)A regular old steel garage door. At least not the size and type I need. Looking at a minimum of four months out no matter which company I go with.

Roy Rolling

(6,905 posts)My daughter is an executive with a large corporation, she has an MBA in “Supply Chain Management” and I have no idea what her job title is.

I’m serious, it’s too complex to remember.

Hortensis

(58,785 posts)understood his son's title either, or what he actually does. But he has a notion of the setting from the industry anecdotes his son fell back on, rather than discuss his work itself. Needing advanced education to be able to understand why a child's work is interesting is a strange thing to happen to a parent.

Sounds like discussion with your daughter'd be interesting.

KT2000

(20,566 posts)how fragile the supply chain can be. Many passenger airplanes have been adapted to take more and more commercial cargo. When passengers quit flying due to covid - it was difficult to find alternatives for the cargo because those were already stressed.

Container ships do lose loads in the middle of the ocean and they have been known to start on fire due to leaking chemicals in the containers. The whole load sinks.

How many containers were stuck in the Suez Canal - the one blocking and the ones waiting. Anyway, the plan is for larger container ships and more capacity. This is the Ever Given stuck in the Suez Canal and it is not even fully loaded. https://www.marketwatch.com/story/container-ships-will-keep-getting-bigger-even-after-the-ever-given-becoming-stuck-in-the-suez-canal-11617637476

Some manufacturers have embraced the low inventory model which left them unprepared for any interruptions. I know of one electronics company that adopted a new model for manufacturing. They started manufacture in the US, sold the unfinished product to a business in China that finished the product, then the Chinese company sold it back to the US. When TFG put the tariffs on China, the US company changed its manufacturing to another Asian country, all the while maintaining low inventory. They were sitting ducks when Covid hit.

I guess the supply chain is vulnerable to any number of disruptions.

LT Barclay

(2,594 posts)items we can't/don't make her to importing necessities.

And China doesn't care. They are only interested in the money. And once they see that we will pay more when supplies are short, "supply chain" issues may become the norm.

Silent3

(15,123 posts)The most time I've ever waited to get my car fixed before this was maybe two or three days -- I don't remember for sure simply because no repair time was ever so long that it sticks out in my memory.

This time I had to deal with both parts shortages and labor shortages.

At first, the only problem was that my "Check engine" light came on, but the car provided no info about the specific problem. I called the dealer (as the car is still under warranty) the day after I noticed the light, but they couldn't make an appointment for me for TEN days. I checked a place further from home, but that only would have cut my wait down to seven days, and saving three days wasn't worth the complication of the extra distance.

Two days later, however, with my appointment eight days off, my car refused to move. I'd put the car into reverse to get it out of my garage, and nothing would happen except the message "Shift to park" appearing on the dashboard. I had to get the car towed to the dealer, which wouldn't have even come up as an issue if they'd given me an appointment right away.

It took 2-3 days before the car even got looked at, and the first thing the dealer discovered was that they couldn't even look further into what the trouble was without ordering a special insulated glove for high-voltage work (my car is a Chevy Volt). That glove, of course, was in short supply.

About two weeks later the glove arrives, which merely allowed them to get to the point where they discovered that a special high-voltage relay needed to be replaced. That part too was in short supply, and took about two weeks to arrive.

When that arrived it still took four days until the work got done. I complained about the delay, saying I thought being without my car for a month should put me at the top of the priority list, only to be told the dealer had other cars that had been waiting two months to get fixed.

The parts shortages I understand. The labor shortage is a bit more mysterious, unless a whole lot of auto mechanics out there are coming down with COVID.

Demsrule86

(68,453 posts)roamer65

(36,744 posts)A lot emptier and more used vehicles in place of where there would be new ones.

Sherman A1

(38,958 posts)At all levels of the supply chain. Worked retail grocery for years before my company jumped on the just in time bandwagon the aisle I was assigned to at the time had 8 pallets of back stock each week, once we were fully on the program it was less that half of one. We were then subjected to the whims of any problems up the supply chain. Warehousing, transportation or any hiccups and we were out of stock.

smirkymonkey

(63,221 posts)For some reason I have not been able to get a jar of Claussen's pickles in months and I am going through serious withdrawal.

"An article in Supply Chain Management Review explains that it has to do with "Tier - 2 supply shortages." Which is a real bummer because according to them that means it's a sustained shortage. The problem is the fact that the amount of glass recycling is down, causing a shortage on glass pickle jars that Claussen uses. That makes a lot of sense, because while we've seen other items such as beef, and toilet paper, and other things bounce back quickly, the supply chain for Claussen pickles is an ongoing problem. Glass recycling is down because of reduced city services for recycling. At one point this summer there was up to an 88% in Claussen Pickles."

However, there seems to be glass jars for other products, so I don't really get it. ![]()