Environment & Energy

Related: About this forumThe use of hydrogen to separate and recycle neodymium-iron-boron type magnets from electronic wastes

https://www.sciencedirect.com/science/article/pii/S0959652615005806

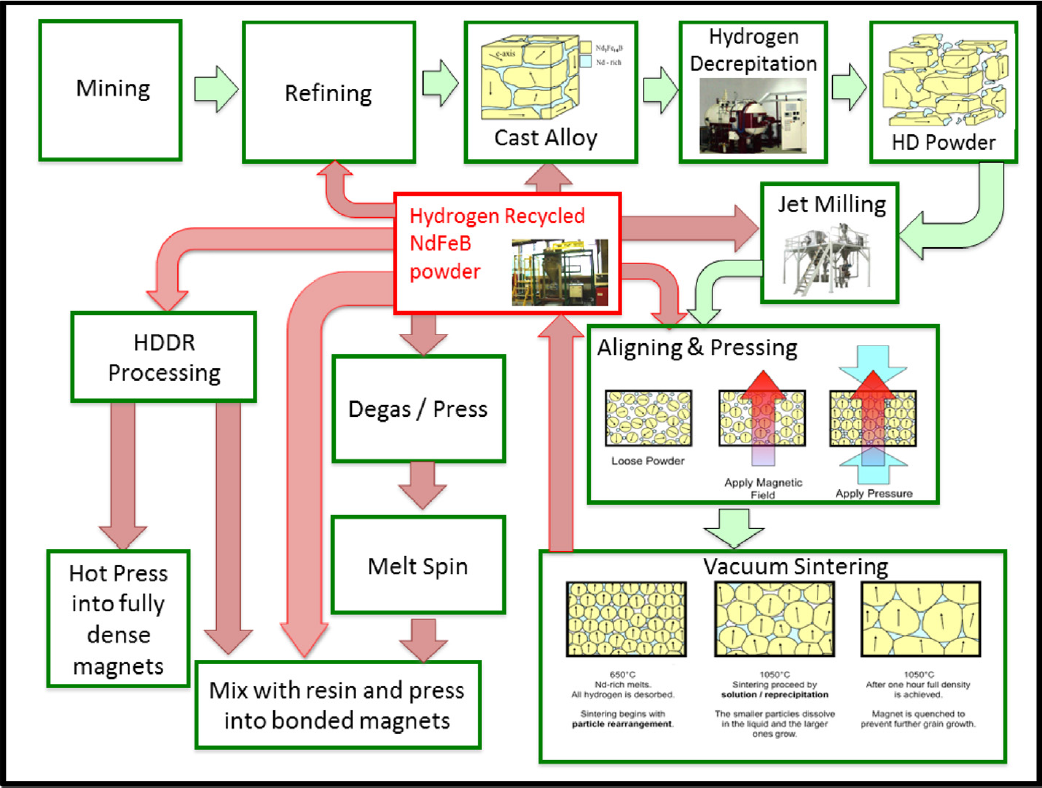

Schematic of possible re-processing routes. Green boxes show primary route for manufacturing a sintered NdFeB magnet. Red boxes and arrows demonstrate where the hydrogen extracted powder can be fed back in to recycle the material. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

The use of hydrogen to separate and recycle neodymium-iron-boron type magnets from electronic waste

(A. Walton, et. al. )

School of Metallurgy and Materials, University of Birmingham, United Kingdom

School of Chemical Engineering, University of Birmingham, United Kingdom

Abstract

The rare earth metals have been identified by the European Union and the United States as being at greatest supply risk of all the materials for clean energy technologies. Of particular concern are neodymium and dysprosium, both of which are employed in neodymium-iron-boron based magnets. Recycling of magnets based on these materials and contained within obsolete electronic equipment, could provide an additional and secure supply. In the present work, hydrogen has been employed as a processing agent to decrepitate sintered neodymium-iron-boron based magnets contained within hard disk drives into a demagnetised, hydrogenated powder. This powder was then extracted mechanically from the devices with an extraction efficiency of 90 ± 5% and processed further using a combination of sieves and ball bearings, to produce a powder containing <330 parts per million of nickel contamination. It is then possible for the extracted powder to be re-processed in a number of ways, namely, directly by blending and re-sintering to form fully dense magnets, by Hydrogenation, Disproportionation, Desorption, Recombination processing to produce an anisotropic coercive powder suitable for bonded magnets, by re-melting; or by chemical extraction of the rare earth elements from the alloy. For example, it was shown that, by the re-sintering route, it was possible to recover >90% of the magnetic properties of the starting material with significantly less energy than that employed in primary magnet production. The particular route used will depend upon the magnetic properties required, the level of contamination of the extracted material and the compositional variation of the feedstock. The various possibilities have been summarised in a flow diagram.

© 2015 The Authors. Published by Elsevier

So, like the great Indium shortage (https://www.democraticunderground.com/112790020) of 2015 that proved to be a bust (https://upload.democraticunderground.com/1127109508) maybe the great neodymium-iron-boron magnet problem of 2018 (https://www.democraticunderground.com/1127117049) will suffer a similar fate.

lagomorph777

(30,613 posts)Will find those useful on political debates. ![]()

NNadir

(33,470 posts)Last edited Wed May 9, 2018, 07:10 AM - Edit history (2)

...neodymium supplies in the long term.

Reading the text, I'm a little surprised to learn that someone thinks this process applies to trashed wind turbines.

Let's consider the failed wind turbine at Østerild By Østerild, 7 MW (peak) turbine with a 154 meter rotor - about 1 and a half US football fields - that was commissioned in June 3, 2015 and decommissioned on February 18, 2018. It operated for 626 days before being ready - if we believe this - for "recycling." It generated a total of 33,682,702 kWh, or 121 trillion joules. A generator with a capacity utilization of 100% operating for 626 days at 7 MW would produce 378 trillion joules, (or 105,168,000 kWh) thus the capacity utilization of this huge hunk of now useless metal for the period of one year 30.2%. The nacelle for this rotting hunk of metal sits at 120.5 meters, almost certainly on a huge think steel pole embedded in a huge concrete base.

One kind of wonders what the EROI that assholes who know very little about energy, engineering, or science always prattle on about when sticking cotton in their ears when someone questions whether this crap is sustainable, which clearly it isn't. When there's no more petroleum to burn to have trucks to haul these giant steel posts around and blades around...

...or coal to refine iron ore and make it into steel, and gas to back this crap up when the wind isn't blowing and the pieces of crap are actually working.

Or, um, neodymium.

Oh wait! Wait! We have here an abstract proving that there's an infinite supply of neodymium, more than enough to take the wind industry from less than 10 exajoules of energy all the way to 580 exajoules "by the 'year such and such" du jour.

I have the full paper corresponding to the abstract linked in the OP before me. I'd be curious to know how the author of this "plenty of neodymium post would imagine the process described therein would be utilized to recycle an Nb/Fe/B magnet set upon a 120.5 steel poll. Perhaps he or she will grace us with the details.

As for me, I don't feel relieved to find out that neodymium itself is "renewable," although, unlike indium, to which I'll turn (again) at the end of this post, since I very much enjoyed the "proof" that the pleurotoxic element indium is also in unlimited supply, said "proof" consisting of googling one's way to the USGS website that records the likely reserves for projected use, the projected use not including the 100% renewables "by the 'year such and such" du jour..

Nevertheless, from the paper before me, it does seem that the authors of the paper are concerned about neodymium supplies, even if I'm not, since I have argued - only to be misconstrued by people who cannot apparently either read or think well - that the main problem with neodymium is not immediately its long term supply, but rather the environmental cost of processing its ores.

The authors write in the text:

In recent years, the supply of rare earth metals has come under considerable strain. China currently provides over 85% of rare earth metals to the world market but, in recent years, began to impose export quotas. This resulted in dramatic price fluctuations for the rare earth metals, in particular, neodymium, praseodymium and dysprosium, the rare earth constituents of NdFeB magnets. According to the EU Critical Materials list (2010, 2014) and the US Department of Energy's energy critical element list (2010), the rare earth metals are classified as at greatest risk of supply shortages compared to those of all other materials used for clean energy technologies.

The authors then note what I've noted in a recent post about so called "clean" so called, "renewable" energy, that "clean energy" isn't clean any more than so called "renewable energy" is renewable.

I'm not concerned at all about the "radioactivity" of thorium. Anyone who went camping in the last decades of the 20th century certainly had some if they had gas lanterns.

They then describe their hydrogen based process, from which they obtain what appears to be gram quantities of neodymium, with an estimated recovery of our 90%. I'd just love to see this process put into practice to "recycle" the huge failed wind turbine at Østerild By Østerild.

As for indium, I'm sure all of the scientists whose works I read on the subject of indium and gallium supplies would be very impressed if someone wrote to them to dismiss their work by reference to a blog post by a poster on Democratic Underground who googled "Indium" and found his or her way to the USGS website.

For example, I recently posted (Analysis of Failure Modes in Kesterite Solar Cells) a link to this paper, Analysis of Failure Modes in Kesterite Solar Cells by researchers aka known as "scientists," as opposed to "100% renewables "by the 'year such and such" du jour"" bloggers on DU who have googled their way to the USGS website. These scientists really need to read blog posts on DU to learn the "alternate facts" that prove that indium, like neodymium is "renewable" and "green."

They wrote:

Among the thin-film solar cell technologies, Cu(In,Ga)(S,Se)2 (CIGS) and CdTe have already demonstrated power conversion efficiency (PCE) values above 22% at laboratory scale and above 15% for large modules.(1) Industrialization of these technologies is already ongoing, with cumulative production over 4 GWp in 2016.(2) However, both of these technologies contain elements that have been listed by the European Commission as Critical Raw Materials (CRM) for the energy sector,(3,4) namely gallium, indium, and tellurium because of their scarcity in the Earth’s crust(5) and their use in other markets. Additionally, progressive implementation worldwide of regulations similar to Restriction on the Use of Hazardous Substances (RoHS) will limit or prevent the use of cadmium in these technologies,(6) both in the absorber layer (CdTe) and in the buffer layer (CdS).

There's those people at the European Commission on Critical Materials again. Apparently they're too stupid to read blog posts on DU linking to the USGS web page on indium.

In that post, I noted that we could always "recycle" indium, although we might not do it ourselves, but rather find poor people in some dire impoverished country to do it for us so we'll be green. I mean working with that stuff destroys lungs,

Serial evaluations at an indium‐tin oxide production facility (Cummings et al Am. J. Ind. Med. 56:300–307, 2013):

previous studies, exposure assessments have been lacking, and the role of serial medical testing in disease detection and prevention has not been evaluated.

There's no similarity here to black lung disease in coal miners by the way, because CIGS solar cells are "green." Maybe we can call it "Green Lung Disease." GLD. I like it.

Recycling, by the way, is both energy intensive and requires the application of environmental stress.

A nice review of the external costs of recycling neodymium as opposed to mining is here:

Comparative Life Cycle Assessment of NdFeB Magnets: Virgin Production versus Magnet-to-Magnet Recycling (Sutherland et al Procedia CIRP 48 (2016) 45–50)

If you access the paper you can find that recycling neodymium from neodymium iron boride magnets reduces most of the environmental impacts for neodymium processing when compared to isolating them from ores:

The impacts are listed in the text global warming, acidification, carcinogenicity, non carcinogenics, respiratory effects, eutrophication, ozone depletion, ecotoxicity and smog. It is shown graphically (figure 3 in the paper) that when compared to the odious practice of lanthanide isolation, these effects are reduced by recycling to between 30%-50% of these effects owing to lanthanide mining.

The references in that paper refer to another hydrogen process similar to the one described in the paper linked in the OP, but somewhat earlier, if one is interested in priority.

Of course, if we're going to be 100% renewable "by the 'year such and such" du jour, as I've been hearing my adult life - and I'm hardly young - we're not going to get by by simply recycling the neodymium in that piece of garbage at Østerild By Østerild. If that happens, we're going to need to mine a lot of neodymium, and iron, and bauxite and coal to get to a few million aerial bird grinders.

I trust you are having a wonderful work week. I had the pleasure of speaking with some very fine scientists today, but they were from the pharmaceutical industry and not the energy industry. But they had some beautiful stuff to say. I learned of some very remarkable new approaches to saving lives that have nothing to do with nuclear power, although nuclear power, by preventing some of the constant losses connected with air pollution also saves lives. As such, as my week's been beautiful thus far, I wish you a week as good as mine has been.