Environment & Energy

Related: About this forumRoman Seawater Concrete Holds the Secret to Cutting Carbon Emissions

(Please note, press release from US Federal Research Lab. Copyright concerns are nil.)

http://newscenter.lbl.gov/news-releases/2013/06/04/roman-concrete/

[font face=Serif][font size=4]Berkeley Lab scientists and their colleagues have discovered the properties that made ancient Roman concrete sustainable and durable[/font]

June 04, 2013

Paul Preuss 510-486-6249 paul_preuss@lbl.gov

[font size=3]The chemical secrets of a concrete Roman breakwater that has spent the last 2,000 years submerged in the Mediterranean Sea have been uncovered by an international team of researchers led by Paulo Monteiro of the U.S. Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab), a professor of civil and environmental engineering at the University of California, Berkeley.

Analysis of samples provided by team member Marie Jackson pinpointed why the best Roman concrete was superior to most modern concrete in durability, why its manufacture was less environmentally damaging – and how these improvements could be adopted in the modern world.

“It’s not that modern concrete isn’t good – it’s so good we use 19 billion tons of it a year,” says Monteiro. “The problem is that manufacturing Portland cement accounts for seven percent of the carbon dioxide that industry puts into the air.”

Portland cement is the source of the “glue” that holds most modern concrete together. But making it releases carbon from burning fuel, needed to heat a mix of limestone and clays to 1,450 degrees Celsius (2,642 degrees Fahrenheit) – and from the heated limestone (calcium carbonate) itself. Monteiro’s team found that the Romans, by contrast, used much less lime and made it from limestone baked at 900˚ C (1,652˚ F) or lower, requiring far less fuel than Portland cement.

Cutting greenhouse gas emissions is one powerful incentive for finding a better way to provide the concrete the world needs; another is the need for stronger, longer-lasting buildings, bridges, and other structures.

“In the middle 20th century, concrete structures were designed to last 50 years, and a lot of them are on borrowed time,” Monteiro says. “Now we design buildings to last 100 to 120 years.” Yet Roman harbor installations have survived 2,000 years of chemical attack and wave action underwater.

…[/font][/font]

NYC_SKP

(68,644 posts)I credit John Smeaton. http://targetstudy.com/knowledge/invention/118/concrete.html

Was his 1759 formula less energy intensive than today's, or more than the Romans'?

I don't know!

madokie

(51,076 posts)I've finished a lot of it but never knew the history. I knew that the Romans had figured out how to make concrete and that their concrete is still getting harder as time goes on. Pretty much the same as ours is today. I know from tearing out concrete driveways that were only a few years old compared to some that is 60-70 years old and there is no comparison in the two, in hardness that is.

NYC_SKP

(68,644 posts)A truly remarkable feat in engineering and design and, as it turned out, materials sciences and chemistry.

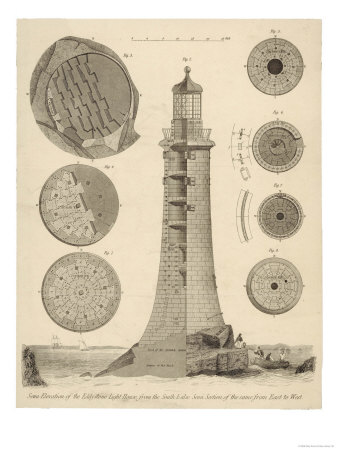

Below is the trunk of his design for the Eddystone Lighthouse, the fourth of five designs on that difficult place, the Eddystone rocks.

It was dismantled and rebuilt ashore, having failed not because of it's design but because of the shifting of it's rock base.

http://targetstudy.com/knowledge/invention/118/concrete.html

Here are the series of designs:

The history of this place and of these designs is fascinating!

![]()